Movement for Responsible Mobility

Making a mobility change

According to the European Environment Agency, road traffic accounts for about one fifth of EU CO2 emissions European Environment Agency (2022): “Transport and environment report 2021. Decarbonising road transport — the role of vehicles, fuels and transport demand”, p. 5, URL (access on 14th September 2023). If we use the eBike instead of other motorised vehicles, especially for personal use in cities, this value can be reduced. eBikes cause neither noise pollution nor exhaust fumes and require little space Word Health Organization, Regional Office for Europe (2022): “Walking and cycling: latest evidence to support policy-making and practice”, p. 26 ff. URL (access on 8th August 2023).

But switching to an eBike is just one of many steps towards more mindful and responsible mobility. For Bosch eBike Systems, the journey begins much earlier: On this page we show you how we are continuously working to improve our product lifecycle - for a more positive impact on our economy, our environment and our society.

Compared to other means of transport, the eBike is a more considerate way of getting around – more flexible, quieter and less CO2 intensive Word Health Organization, Regional Office for Europe (2022): “Walking and cycling: latest evidence to support policy-making and practice”, p. 26 ff. URL (access on 8th August 2023).

The eBike is the next evolutionary step in cycling. Even though the CO2 footprint of an eBike is larger than that of a bicycle: eBikers ride much more frequently than cyclists without an electric drive and on longer journeys Castro et. al (2019): “Physical activity of electric bicycle users compared to conventional bicycle users and non-cyclists: Insights based on health and transport data from an online survey in seven European cities”, in: Transportation Research Interdisciplinary Perspectives, V1 2019, URL (access on 8th August 2023).

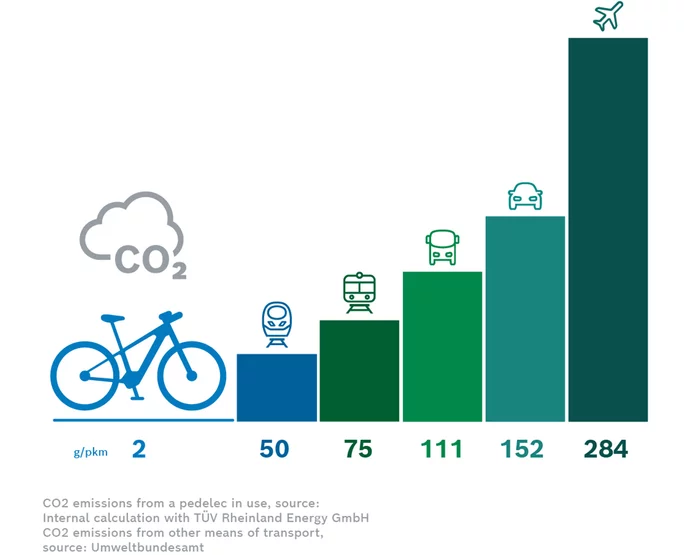

CO2 emissions in comparison

According to the World Health Organization cycling is a response to issues and challenges of our time such as resource scarcity, climate change or urbanization Word Health Organization, Regional Office for Europe (2022): “Walking and cycling: latest evidence to support policy-making and practice”, p. 1 ff URL (access on 8th August 2023).

Although eBike components, such as the battery or the drive, cause more emissions during production than standard bicycles, people on eBikes ride much more often and for significantly longer distances Castro et. al (2019): “Physical activity of electric bicycle users compared to conventional bicycle users and non-cyclists: Insights based on health and transport data from an online survey in seven European cities”, in: Transportation Research Interdisciplinary Perspectives, V1 2019, URL (access on 8th August 2023). In everyday life, the eBike can be used instead of the car in many situations, such as going shopping with an eCargo bike.

Let's look at the graph: If you only consider the time spent on the road with your eBike, the power consumption results in an average CO2 emissions value of around 2g/km, depending on the power mix. In comparison, according to the Federal Environment Agency, a car emits about 152g CO2/passenger kilometre (pkm), while public transport emits between 50 and 111g CO2/pkm. The graph shows that compared to all other means of transport, eBikes are significantly lower in emissions.

On the road to more responsible mobility with the eBike.

We have compiled some tips and tricks for more considerate eBiking. From more efficient use of the battery for even greater range and a longer service life, to environmentally conscious behaviour on the trail.

The battery is responsible for a large part of your eBike's CO2 footprint. With the right handling and care, you can optimise the service life of your eBike's battery. Find out more about optimal use of our batteries in our Battery Guide.

Our commitment to responsible mobility.

Shaping a desirable future is a shared responsibility. As part of the Bosch Group, we have a common goal: We intend our products to contribute to a more desirable future in which people are mobile in a considerate and flexible way with greater riding enjoyment.

The overriding Bosch sustainability strategy ‘New Dimensions – Sustainability 2025’ describes the company's goals based on six fundamental issues: climate action, health, human rights, water, circular economy, and diversity Robert Bosch GmbH: “Comprehensive sustainability strategy and consistent compliance”, URL, (access on 8th August 2023).

At Bosch eBike Systems, we are particularly committed to three strategic pillars of the global sustainability strategy:

- Reducing the CO2 footprint of our products: We evaluate product-specific environmental aspects within the framework of our life cycle analysis.

- Responsibility and transparency in the supply chains: We assess the social and ecological risks along the value chain.

- Development of a functioning circular economy: We regard repairability and ease of maintenance as product development criteria

CO₂ footprint and life cycle analysis

We evaluate product-specific environmental aspects at every stage of the life cycle and work continuously to improve them.

The CO2 footprint over the entire life cycle is a key metric when comparing the sustainability of products. In a so-called Life Cycle Assessment (LCA), we evaluate product-specific environmental aspects in each life cycle phase - from procurement, manufacturing and use to disposal.

Together with TÜV Rheinland TÜV Rheinland is in it´s own words “one of the world’s leading testing service providers” – “as an independent expert”. See more on www.tuv.com/world/en/ (access on 8th August 2023), we have calculated the average CO2 footprint for an eBike and for the Bosch eBike system components (drive unit, battery, display, control unit) in detail and identified the greatest potential savings.

The result: Over its entire life cycle - from production to recycling - an eBike generates a CO2 equivalent of approximately 300kg. Around 75% of CO2 emissions are produced by materials and manufacturing, around 15% during actual use of the eBike, and the remaining 10% or so during transport, packaging and recycling. Approximately 36% (121kg) of the total footprint is produced by the eBike system, in other words: the components that turn a bicycle into an eBike. The lion's share of this is produced by the eBike battery.

Using this data, we are working to identify areas where CO2 emissions can be reduced, which will then influence the design of future products.

Responsibility in the supply chain

We are working on a systematic analysis of the social and ecological risks all along the value chain. Our goal is to further develop and strengthen transparency in our supply chain for all Bosch eBike products.

Transparency

A key pillar of our sustainability activity is a transparent supply chain that enables comprehensive tracing of critical raw materials. The eBike battery is the focus here. For example, we have developed a mapping in collaboration with battery cell suppliers, to find out important details about the supply chain - right back to the procurement of raw materials at the mine.

We intend to broaden the scope of this to include other eBike system components that contain materials such as aluminum and magnesium - such as the drive system and the control unit. The results will also be verified by appropriate assessments.

Want to learn more about the Bosch Global Supply Chain Standards? Further information is available here.

Cobalt in battery cells

Batteries are becoming more and more powerful in terms of capacity. This innovation has great advantages, not just technical ones: Through further development of the battery cells by our suppliers, the cobalt content in the cathode of the eBike battery cell has been reduced by 65% compared to the technology used previously.

Circular economy

We are working to offer and improve recycling solutions in all our markets, e.g. by jointly establishing or advising industry solutions and by contacting recycling companies directly. The circular economy pillar also includes the development of new packaging and transport concepts.

Remanufacturing of eBike drives

Repairability and easy maintenance are two of our most important criteria in product development and essential cornerstones of a functioning circular economy. We provide independent bicycle retailers with the knowledge and tools to carry out maintenance and minor repairs to the drive unit. Bosch eBike drive units that are replaced free of charge under warranty and goodwill are reconditioned, which means that the drives are technically overhauled and, after a final test, are made available to the customer again with full functionality.

Recycling eBike batteries

Once a battery has reached the end of its lifetime, it must be disposed of appropriately. We would urge the users of our eBike systems to take defective or disused batteries to their local specialist dealer, who will ensure they are disposed of in the appropriate manner. Appropriate recycling practices save resources and valuable raw materials are returned to the materials cycle.

New packaging and transport concepts

Since September 2020, eBike drives from Bosch eBike Systems have been delivered in easy-to-recycle moulded fibre packaging instead of polystyrene. This not only saves material and recycling costs, but also ensures optimised packing density during transport and storage. We also deliver our products on Euro pallets, which are exchanged and reused after unloading.

Sustainability-FAQ

eBike as a sustainable means of transport

The bicycle is one of the most sustainable means of transport there is. Because of the very low utilisation of material and vehicle weight, it enables flexible, emission-free, quiet and climate-friendly mobility. What's more, regular cycling is also good for your health.

The eBike is the next evolutionary step in cycling. It permits longer trips, further distances and overcoming greater differences in altitude. Overall, eBikes significantly expand the possibilities of use without significantly altering any characteristics, or CO2 emissions in the production, of the eBike compared to the bicycle. This is the case even though more energy is required for the battery and drive system than for the bicycle, especially in production. But eBikers increasingly use their electric bikes in everyday life, often as an alternative to cars and other means of transport. Furthermore, eBikers use their eBikes two to three times more often and travel significantly longer distances. In addition, the required energy consumption is very low, averaging around 7 Wh of electricity per kilometre travelled.

The average power consumption of an eBike with a Bosch eBike system is about 7Wh/km. This value results from the R200 range test for pedelecs with a Bosch eBike system.

Looking at the CO2 emissions caused through electricity consumption, the average CO2 value is 2-5 g/km, depending on the electricity mix. When charging with green electricity, eBike use even completely eliminates CO2 emissions. In comparison, according to the Federal Environment Agency, a car accounts for around 150g CO2/passenger kilometre (Pkm) and public transport between 30 and 80g/Pkm CO2.

Together with TÜV Rheinland Energy GmbH, we have calculated and evaluated the product's carbon footprint according to ISO14067. Over the entire service life of an eBike (incl. all phases: from manufacturing, packaging, transport to use and recycling), the average CO2 footprint is 300 kg-CO2-eq.

This means that the footprint of an eBike is roughly twice that of a conventional bicycle. This is an average value, and it may differ, depending on the model. Over its entire service life, the eBike has an estimated carbon footprint of about 15-25 g/km, depending on the total mileage travelled. If we consider the pure use phase and therefore the emissions caused by electricity consumption, the average CO2 value is 2-5 g/km, depending on the energy mix.

Over the entire life cycle of an eBike (incl. all phases: from manufacturing, packaging, transport to use and recycling), the average CO2 footprint is 300 kg-CO2-eq. This means that the footprint of an eBike is roughly twice that of a conventional bicycle. This is an average value, and it may differ, depending on the model.

For an objective comparison, however, it must be taken into account that eBikers use their electric bike to a greater extent in everyday life and therefore frequently use it to replace a car or other means of transport. Moreover, eBikers use their eBikes two to three times more frequently and travel significantly longer distances.

Overall, an eBike has an average carbon footprint of 300 kg-CO2-eq. Around 120 kg-CO2-eq of this is attributable to the Bosch eBike system.

After only approx. 800 eBike kilometres, the emissions for the eBike system are amortised when travelling by eBike instead of by car, and the emissions for the entire eBike after 2000 eBike kilometres.

These figures are average values. They may differ depending on the model.

Sustainability at Bosch eBike Systems

General

For Bosch, climate protection is an essential part of corporate responsibility. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral overall (scopes 1 & 2) since 2020. We achieved carbon neutrality by using four levers: increasing energy efficiency, generating our own energy from renewable sources (new clean power), purchasing electricity from renewable sources (green electricity), and – as a last resort – offsetting residual CO2 emissions. In 2022, residual emissions of 0.7 million tons of CO2 were offset through carbon credits. Scopes 1, 2, 3 are used according to the Greenhouse Gas Protocol Corporate Accounting and Reporting Standard.

Sustainability also plays a central role at Bosch eBike Systems and is part of the corporate strategy. At Bosch eBike systems, we are particularly committed to three strategic pillars of the global sustainability strategy:

- minimizing the carbon footprint of our products,

- responsibility and transparency in the supply chains and

- the development of a functioning recycling economy.

More information can be found here.

Cities face huge challenges in the 21st century. The world's population is growing, resources are dwindling, and our climate is changing. Solutions are required. E-mobility can make a significant contribution to sustainable city development and a liveable urban environment. Pedelecs in particular offer great opportunities. They help save resources as well as reducing emissions. Pedelecs are an effective and efficient means of transport, particularly over short distances. People who ride eBikes get around faster, cheaper and with less environmental impact. Pedelecs have great potential in terms of transport policy, especially in urban areas.

Every time we develop a new product or enhance an existing one, we look at how we can reduce the impact of our products on the environment over their entire life cycle. A major factor here is the consistent reduction in the use of materials - we always develop and design subsequent generations of our components to be smaller, more compact and lighter. By reducing the number of parts, we cut down the amount of material required: fewer raw materials are needed and the effort involved in development and production is significantly simplified. One example of this is the reduction in the weight of our drive units. The Performance Line CX in the Bosch eBike system 2 has achieved weight savings of approx. 25% compared to the previous model. By standardising our products and limiting the number of variants and parts, we can scale the manufacturing processes, leading to a reduction in the energy required per part. Further examples can be found in our packaging strategy. Since September 2020, our drives have been delivered to our customers in sustainable moulded fibre packaging. Following extensive safety testing, we were also able to eliminate the use of plastic outer packaging for our PowerTube batteries, saving about a quarter of the CO2 emissions for this packaging.

Responsibility in the supply chain

As a division of Bosch, Bosch eBike Systems is integrated into overall company's plant network. The components for our eBike systems are developed at the Bosch eBike Systems headquarters in Reutlingen, Germany. The drives and the batteries are produced and consolidated at the Bosch plant in Miskolc, Hungary. Most of the production and consolidation of the batteries also takes place at the Bosch plant in Miskolc, Hungary, and some in Penang, Malaysia.

Bosch eBike Systems does not purchase any raw materials such as lithium, but buys them as part of the cells from lithium-ion cell suppliers. A key pillar of the sustainability activities in the eBike area is a transparent supply chain that enables comprehensive tracing of so-called critical raw materials. Comprehensive information on the supply chain through to material procurement, is requested from our cell suppliers and traced. In general, our suppliers have to meet stringent requirements based on the principles of the UN Global Compact, the core International Labour Organization (ILO) standards and other more stringent Bosch standards.

Bosch eBike Systems aims, in principle, to provide spare parts availability for at least six years after the products were last delivered to the eBike manufacturer. In individual cases, however, we may not be able to meet this target if, for example, our suppliers are no longer able to provide individual components. If necessary, we will propose alternative components, e.g. upgrades.

Circular economy

The use of materials with recycled content is examined in every development project and critically reviewed, particularly with regard to product requirements and safety standards. We will also continue to drive this forward in the future. The current status is that the proportion of recycled materials in eBike components is still low. The material mix in our products is designed for the specific application and therefore must meet high requirements in terms of strength and durability. Optimised reliability and reproducibility. In the case of packaging materials, we examine how the material mix can be designed to be as environmentally friendly as possible in order to reduce the use of disposable packaging, for example, and to continuously increase the use of sustainable packaging materials and reusable packaging. One example can be found in our packaging strategy. Since September 2020, our drives have been delivered to our customers in moulded fibre packaging.

The ability to retrofit and repair are key issues in the context of sustainable product development, and therefore an important part of our sustainability strategy.

Maintenance and minor repairs to the drive unit can be carried out by specialist dealers. This can include, for example, use of a drive unit repair kit, relubrication or the replacement or retrofitting of bearing protection rings. If a major fault is detected, the motor will be picked up from the dealer by Bosch. In some cases, we remanufacture the drive units during a service case. This means that the drives that qualify following appropriate testing are reconditioned and, after an "end-of-line" test, are made available to the customer again with full functionality.

However, we also always consider repair concepts in the context of product safety. For Bosch eBike Systems, the safety and reliability of its products are paramount. Thus, if a product is damaged, it may be that a repair is not feasible under these aspects. In such cases it is necessary to replace the entire product. It is important to Bosch to find the best possible solution, so that the eBiker can use their bike quickly again and continue to enjoy it for a long time.

Electric devices can be handed in at any recycling centre. The return of small electric devices to specialist dealers is also possible, provided the showroom exceeds 400 sqm. Prior to disposal, all batteries which are removable must be removed from the electric device and handed in at a battery collection system. Please note that personal data may be stored in displays and delete this as necessary prior to disposal.

Sustainability of the Bosch eBike battery

General

Cylindrical lithium-ion cells are used in Bosch eBike batteries. The cell technology is very similar to the cells used in some electric vehicles. About 5,000-8,000 cylindrical cells are used in an electric car, compared to just 40 to 60 for the most common eBike batteries. Therefore, one electric car corresponds to an average of about 130 eBikes in terms of the number of cells used.

The lithium-ion cells used in Bosch eBike batteries are state of the art. Currently, cobalt is still required: Cobalt is responsible for high energy density in battery cells and thus improves the performance of the battery. Together with our suppliers, we are working on further developing the battery cell technology in order to continuously reduce the proportion of critical raw materials such as cobalt in eBike batteries. Since 2013, the cobalt content in the cathode has already been reduced by 65%.

You can hand in your old or defective eBike battery free of charge to any bicycle retailer, who will recycle it in an environmentally friendly way. No purchase of a new battery is required to do so.

Please note that heavily damaged batteries should not be touched with bare hands, as electrolyte may leak out, causing skin irritation. Please keep any defective batteries in a safe place outdoors, with the contacts taped off, and take them to your bicycle retailer for proper disposal as quickly as possible.

The first priority for our products, including our batteries, is a safe design. High quality and safety standards enable robustness and durability. Optimally adapted cell specification, and lifetime-optimising electronics, help maximise the service life and energy throughput of the battery, thus ensuring the most sustainable deployment of the materials used. With appropriate use and treatment, the distance covered by a Bosch eBike battery during its service life can reach up to 60,000 km. In order to keep the ecological impact of the batteries low, we try to keep the proportion of so-called critical raw materials in the cells as low as possible when developing of the products while at the same time increasing the proportion of recycled materials, while complying with safety requirements. Since 2013, for example, the cobalt content in the cathode of battery cells has already been reduced by 65%. Furthermore, by supporting our cell suppliers, we ensure that we can trace the entire supply chain to ensure more socially responsible extraction of raw materials.

Repair

Some providers claim they can recondition batteries. Bosch strongly advises against this because the safety, and optimum interaction with the Battery Management System, cannot be guaranteed in this case. In addition to the safety risk opening or modifying the battery may void warranty or guarantee claims.

Before buying a Bosch eBike battery you can check whether information is available for the relevant battery serial number.

You will find an eBike battery check here.

For safety reasons, faulty, old or "worn out" batteries cannot be repaired or refreshed. Lithium-ion batteries are complex, finely tuned systems with a high energy content. Correct function and optimum interaction with the Battery Management System can no longer be guaranteed if a battery is repaired. In addition, when the battery is re-assembled, the housing seal can no longer be assured. For safety reasons, batteries must pass extensive series tests in accordance with national and international legislation and normative requirements before they can be placed on the market. These series tests are not feasible for an individual repaired battery due to the number of test samples required. This includes, for example, leakage testing, as well as overcharging and short-circuit tests. If these tests are not performed, there is a high risk that e.g. moisture penetrates the battery and, in the worst case, causes a short circuit and thus a hazard. All of this can have safety-relevant consequences. For safety reasons Bosch strongly advises against having batteries repaired.

Reuse

Our batteries are specially designed and certified for use with eBikes. We cannot guarantee reliable operation in other application areas.

Therefore, we strongly discourage second use and consider the proper return of defective or used lithium-ion batteries for recycling to be the best method. New recycling processes recover valuable raw materials to a large extent, so that they can be used to produce new cells. In addition, the recycling processes are considered to be environmentally friendly and provide a positive CO2 balance through the recovery of raw materials.

Recycle

When a battery has reached the end of its life, it must be disposed of appropriately. The GRS battery return system operates in Germany. We urge the users of our eBike systems to take defective or disused batteries to their local specialist dealer, who will ensure that they are disposed of in the appropriate manner. Recycling is free for eBikers and dealers.

Appropriate recycling practices save resources and valuable materials are returned to the raw materials cycle. This means that raw materials such as aluminium, copper, cobalt or nickel can be recovered with high recycling efficiency and made available for new products.

The legal basis for recycling is regulated at national level. Responsibility for recycling lies with the battery manufacturer. However, as soon as the eBike crosses a national border as a product, the importer automatically becomes the manufacturer. In countries outside Germany, this is the bicycle manufacturer or bicycle retailer. Because of this national aspect, Bosch eBike Systems can only provide a direct solution for battery recycling in Germany. In all other markets in which we are active, e.g. the USA, Canada, Australia or New Zealand, we provide our customers with the best possible support in this regard, and promote country-wide industry solutions if these don't yet exist in some areas.

Bosch eBike Systems is in contact with many recycling companies and supports new and sustainable recycling methods. The efficiency of recovery depends on the recycling process. New recycling processes can have a recycling efficiency of over 90%.